Overview

The ALL IN ONE Heat Exchanger (HX) is the next-generation Plate type, Crossflow, Air to air heat exchanger engineered for superior Indirect Evaporative Cooling (IEC) performance. The IEC operations refer to the two separate airflow streams within the exchanger that enable cooling without adding moisture to the supply air. This technology is designed to deliver high cooling efficiency, significant energy savings, and long-term operational reliability for both industrial and commercial applications.

How It Works

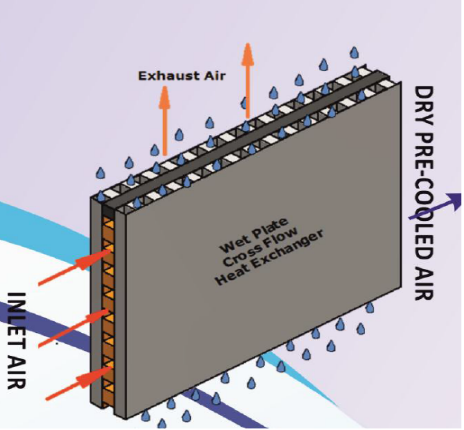

- Primary (Dry) Air Stream: Warm supply air passes through the dry channels of HX, separated by thin engineer polymer plates.

- Secondary (Moist) Air Stream: Exhaust air flows through the wet channels where a thin film of water is present.

-

Heat Exchange Process:

- Heat from the dry channel passes through the plate into the wet channel.

- The heat evaporates the thin water film on the wet side.

- The primary air is cooled sensibly (temperature reduction without moisture addition).

- The secondary air absorbs the moisture and is exhausted.

This crossflow arrangement ensures zero moisture carryover to the supply air and enables consistent, reliable cooling performance.

Performance & Energy Savings

- ALL IN ONE HX-based IDEC systems can replace conventional air-conditioning in some comfort cooling as well as ventilation applications, using up to 30% less energy.

- Indirect-Direct Evaporative Cooling (IDEC) systems can completely eliminate conventional HVAC systems in certain climates.

- Pre-cooling with ALL IN ONE HX s reduces load on DX or chilled water cooling coils in Hybrid AHUs and Treated Fresh Air (TFA) units.

- Energy Savings Examples

- IEC assisted TFA: Up to 30% less energy compared to conventional TFAs.

- IEC assisted Hybrid AHU: Up to 30% less energy while delivering three times more fresh air to conditioned spaces.

Key Features

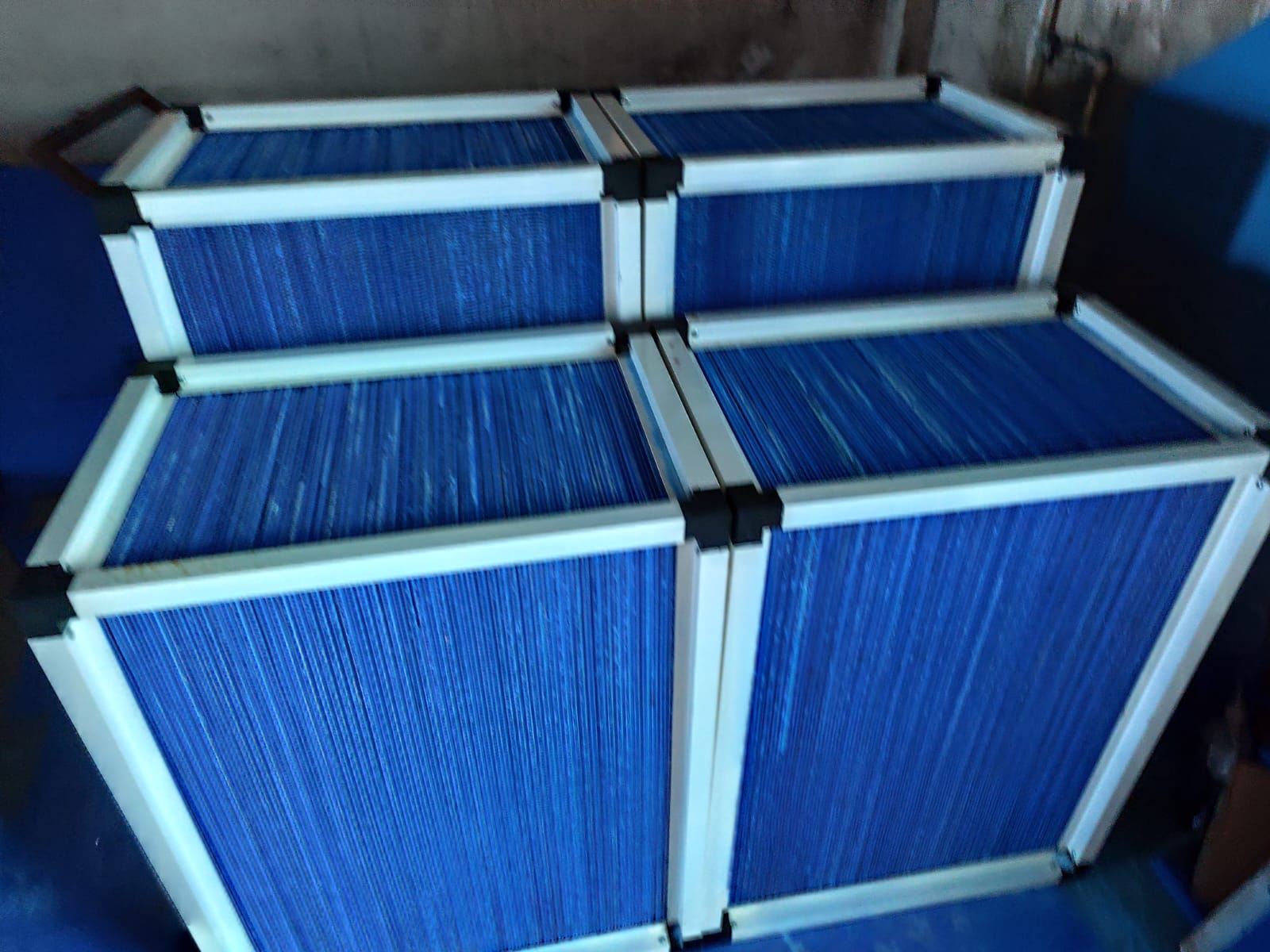

- High-Efficiency Construction in Engineer Polymer - Lightweight, corrosion-resistant, and optimized for IEC.

- Crossflow Plate-Type Design - Low pressure drop and effective thermal separation between air streams.

- Low Leakage - Ensures high reliability in maintaining separate dry and moist streams.

- Low Fouling & Consistent Performance - Smooth polymeric surfaces reduce scaling and dirt accumulation.

- Modular & Scalable - Easy to configure for different capacity requirements.

- Environmentally Friendly - No refrigerants, reduced energy use, and lower carbon footprint.

Applications

- Comfort cooling in Industrial and commercial buildings

- Process cooling

- Cooling of large working spaces like warehouses

- Ventilation for atriums, food courts & industrial kitchens

- Comfort cooling for malls, auditoriums and dining areas.

- Hybrid HVAC systems

- Treated Fresh Air systems

- Compressor-less cooling solutions

Why Choose ALL IN ONE HX

The ALLIN ONE Heat Exchanger provides consistent performance, low operating costs, and sustainability benefits without compromising on comfort or air quality. By reducing dependence on energy-intensive air-conditioning systems, DAMA supports green building goals and climate-conscious cooling strategies.

Technical Parameters - ALL IN ONE HX

| Type | Air to air Plate type HX |

|---|---|

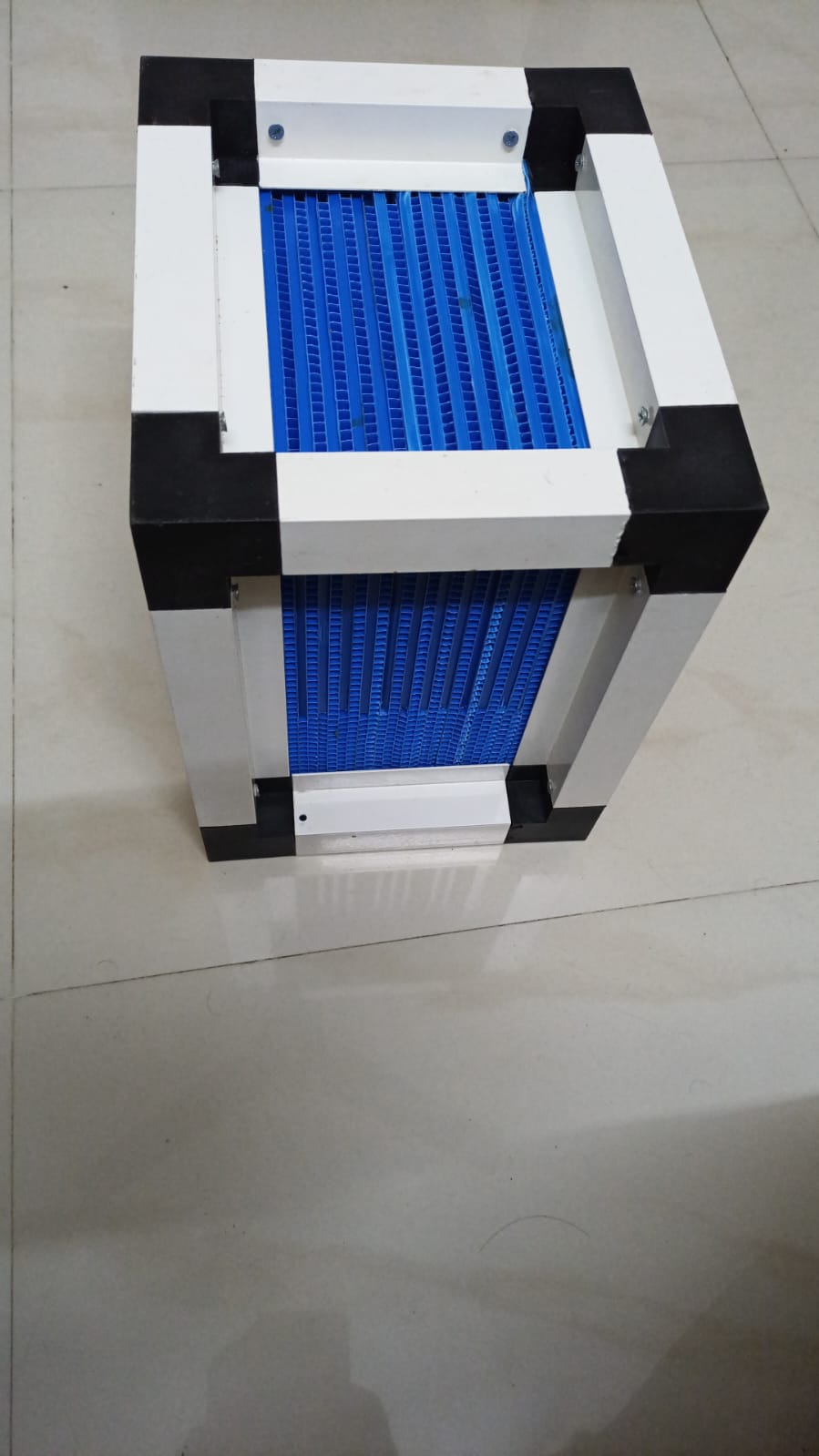

| Construction | One side Wet, parallel plate HX in Cuboid geometry with AL extruded channels housing. Special case construction as Cub geometry |

| Material | Engineering polymer - Polypropylene High grade polymer 700 to 1500 GSM Air leakage less than 0.1% under pressure of 700 Pa |

| Wet Section | Specialty coating of inert material to ensure thin layer evaporation Antifungal, Bacteria static hydrophilic coating |

| Flut Size | Typically 5-6 mm |

| Pressure Drop | 10mm / 100 Pascals @ 500 FPM |

| Normal Effeciency | 65% plus |

| Peak Effectiveness | 80% plus |

| Dimensions | Standard modules W x D x H - in mm 660 x 460 x 660 660 x 460 x 860 660x460x1060 600 x 460 x 1200 Custom made size can be available as per design conditions. |